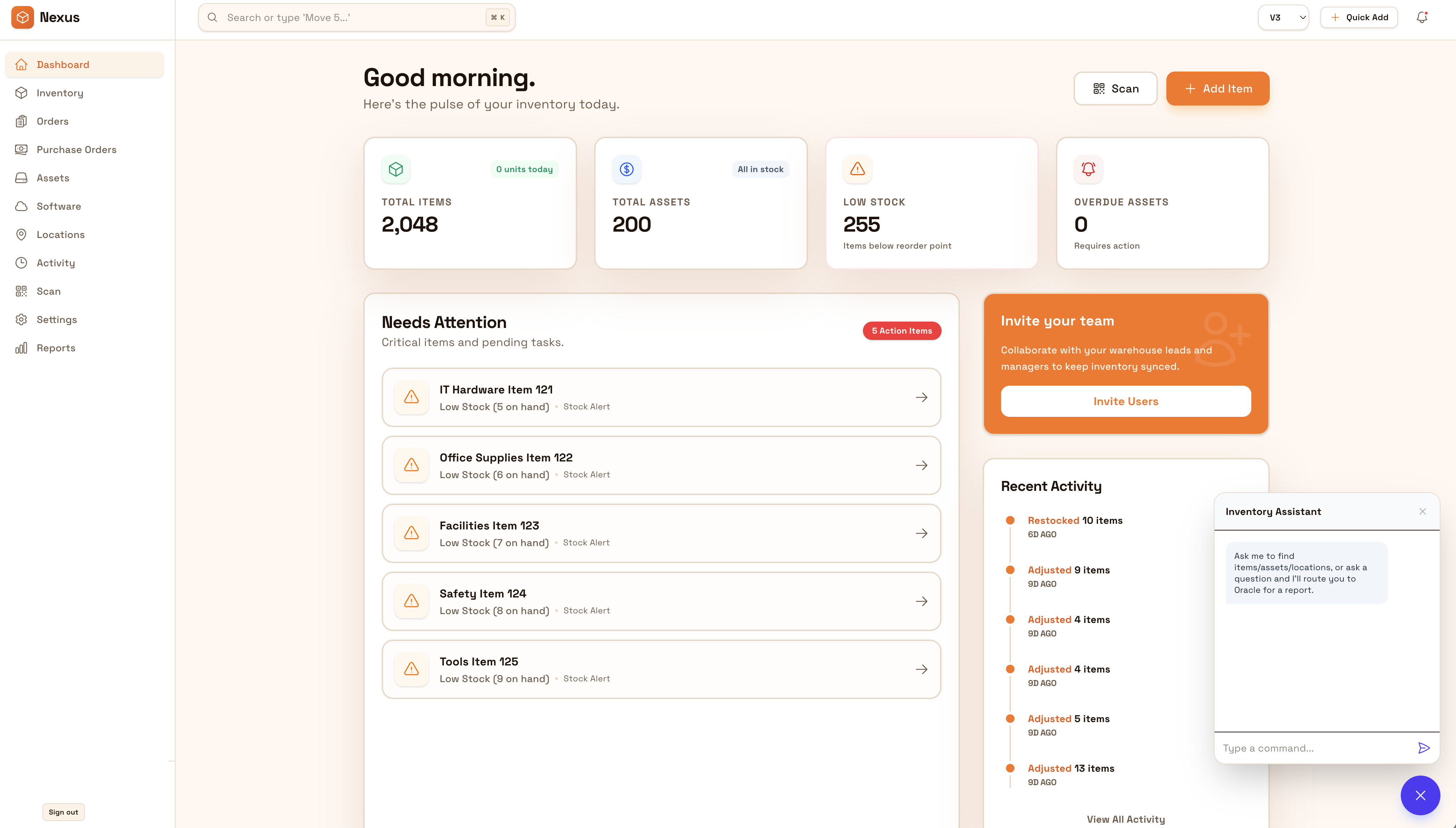

Speed erodes accuracy

When movement is fast, small mistakes compound. Standardize receiving and transfers so each event is traceable.

Run high-velocity receiving, moves, and cycle counts without sacrificing accuracy. Keep transfers traceable, reduce pick errors, and maintain a clean history for reconciliation and client reporting.

Run high-velocity receiving, moves, and cycle counts while staying accurate. Keep transfers traceable and export clean history for clients, reconciliation, and audits.

Warehouses win on speed, but they survive on accuracy. Inventory operations give teams a consistent way to receive, move, and count stock—so transfers are traceable, variance stays low, and customers get what they expect.

Most teams start here. IO helps you reduce drift, keep accuracy high, and maintain a trail you can trust.

When movement is fast, small mistakes compound. Standardize receiving and transfers so each event is traceable.

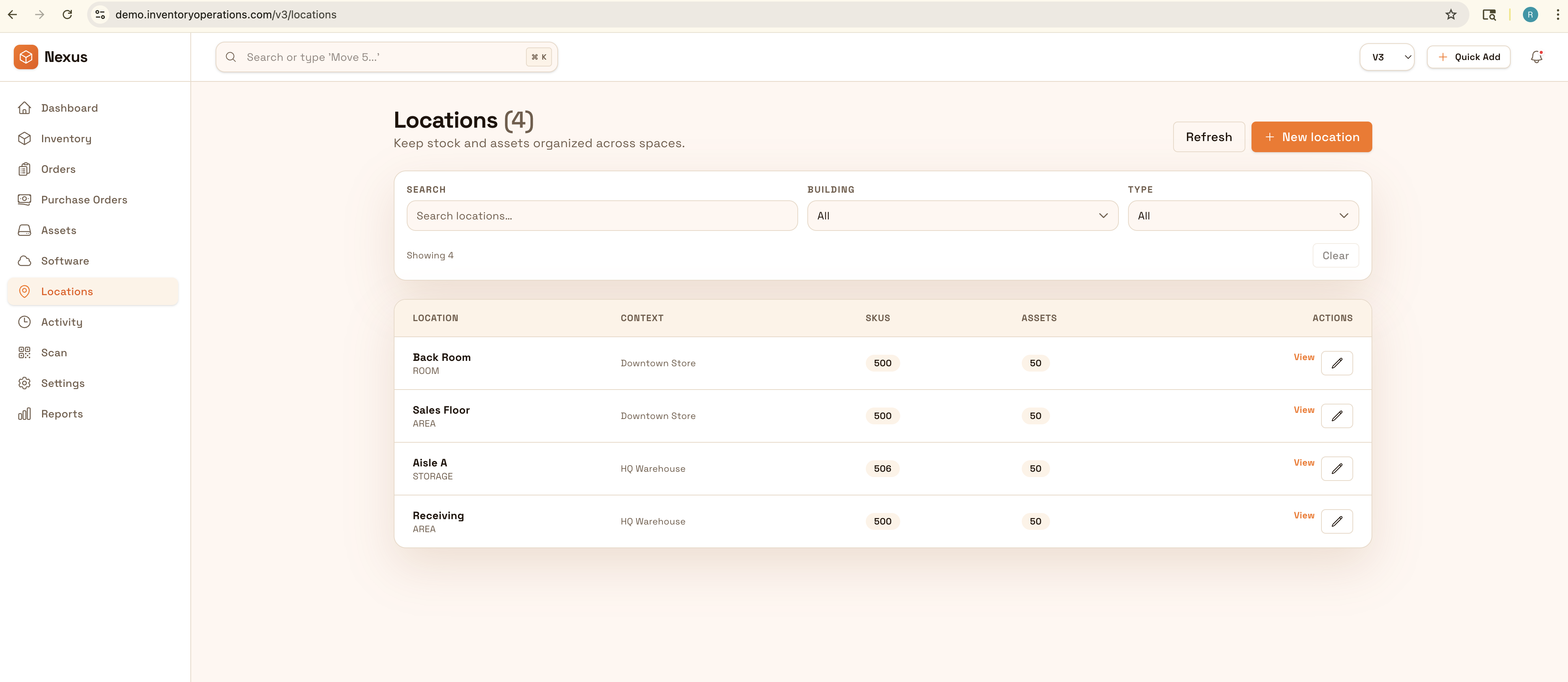

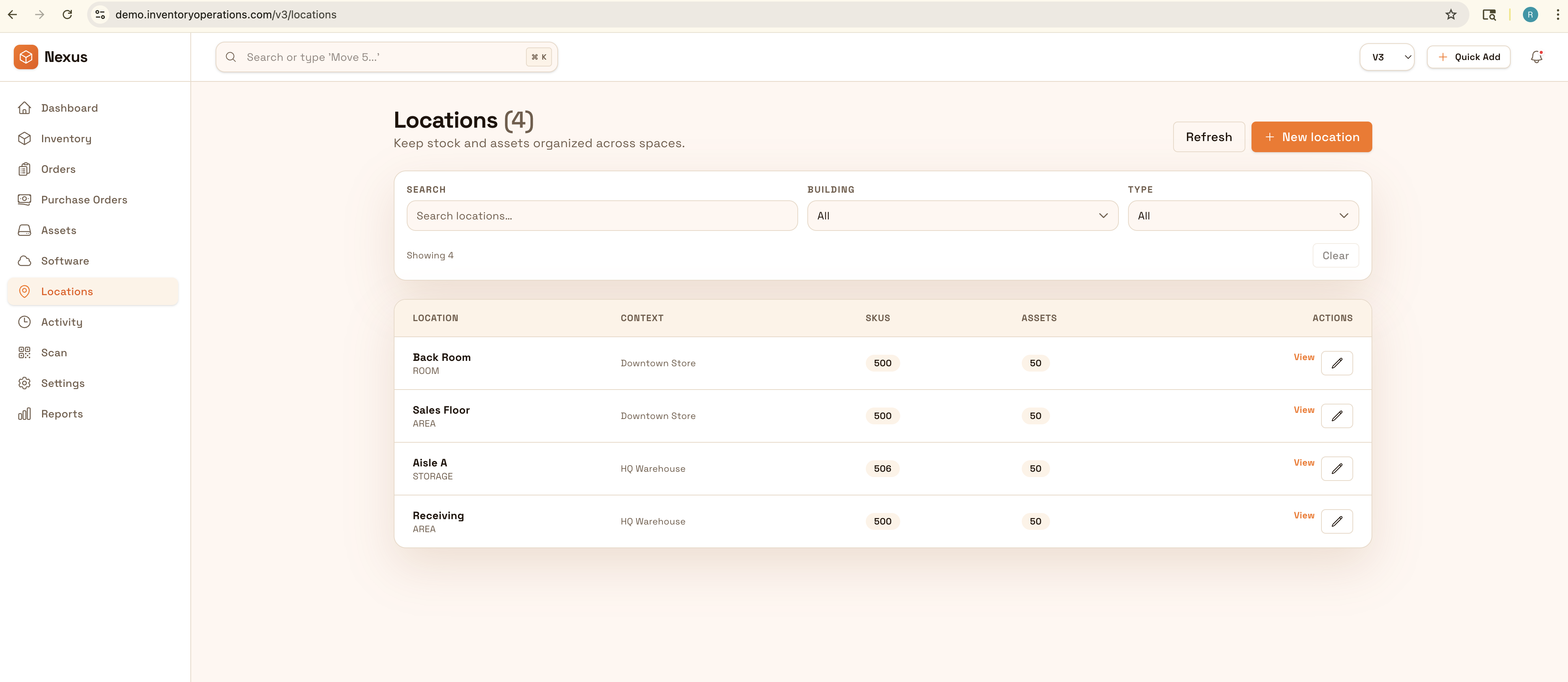

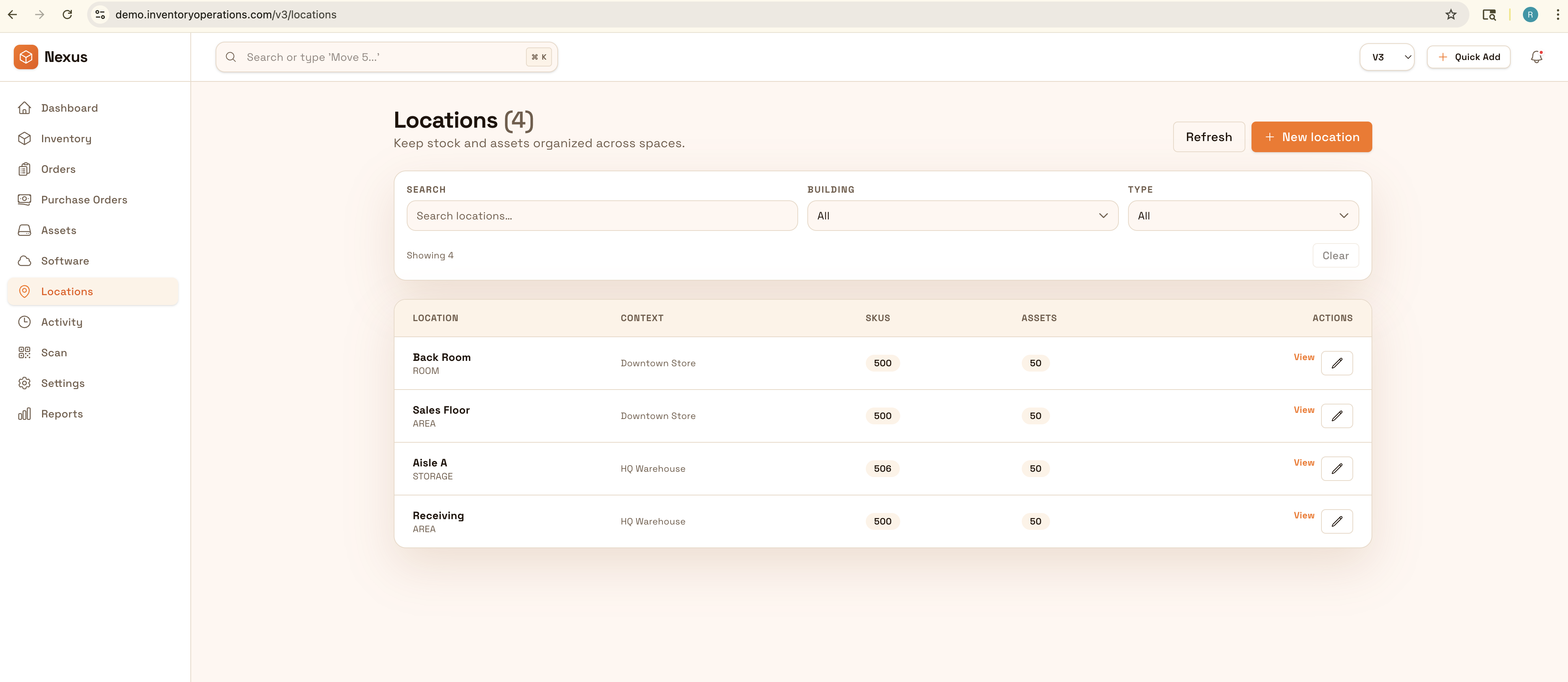

If locations aren’t consistent, teams waste time searching and picks go wrong. A clean location map reduces friction.

Clients and operations need answers quickly. A clean movement trail and exports reduce investigation time.

IO standardizes tracking, controls, and evidence—so teams can operate confidently across sites and stakeholders.

• Receiving details and put-away destinations • Bin-level moves and transfers • Cycle counts and reconciliation notes • Adjustments with reasons and approvals • Exports for client reporting and audits

Record what arrived and where it was stored so availability starts accurate.

Transfer stock between bins with source/destination events to keep locations trustworthy.

Count high-velocity areas frequently to keep accuracy high without shutdowns.

Document variance and export summaries for operations and client expectations.

Tell us your compliance and operational requirements. We’ll recommend the right rollout.

Control adjustments and preserve who/when/why for every movement so audits, reviews, and client questions have defensible answers.

The biggest wins are usually accuracy, speed, and defensible accountability.

Yes—model sites → zones → bins to keep movements traceable.

Not required, but scanning accelerates receiving, transfers, and cycle counts while reducing errors.

Standardize receiving and transfers, then rely on cycle counting to prevent drift.

Yes—exports support client reporting, reconciliation, and audit expectations.

Start with receiving + put-away and the core location map, then add cycle counts.