Variance causes line interruptions

Missing components stall production. Better location accuracy and repeatable counts surface issues earlier.

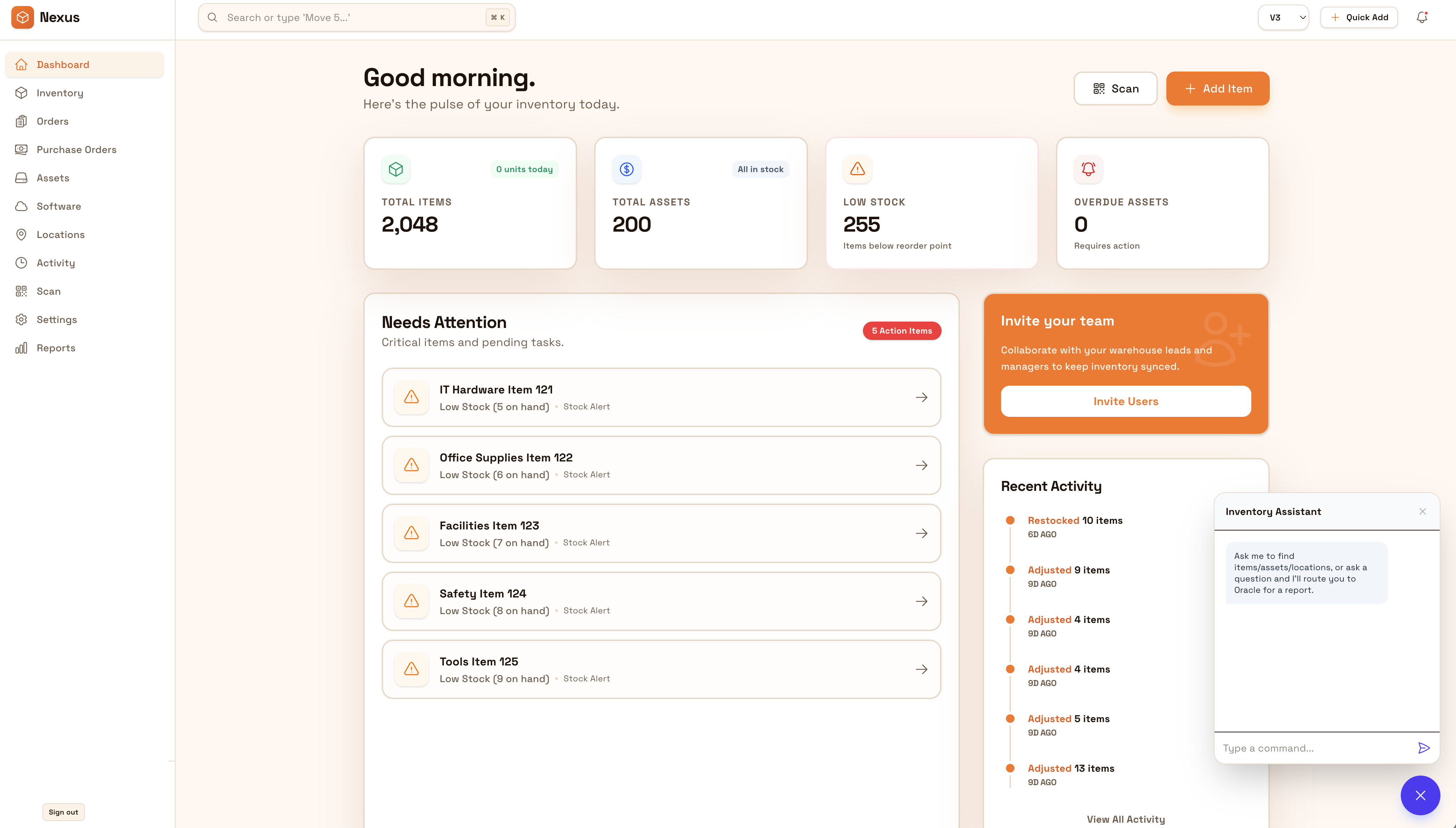

Keep parts, WIP, and finished goods aligned across lines and warehouses with traceable transfers and repeatable counts. Reduce production interruptions by surfacing variance early and standardizing reconciliation.

Keep parts, WIP, and finished goods aligned across lines and warehouses. Standardize transfers and counts so variance is visible early and production interruptions drop.

Manufacturing depends on having the right materials and parts at the right time. Inventory operations reduce line interruptions by keeping WIP, transfers, and counts consistent—so variance is surfaced early and reconciled fast.

Most teams start here. IO helps you reduce drift, keep accuracy high, and maintain a trail you can trust.

Missing components stall production. Better location accuracy and repeatable counts surface issues earlier.

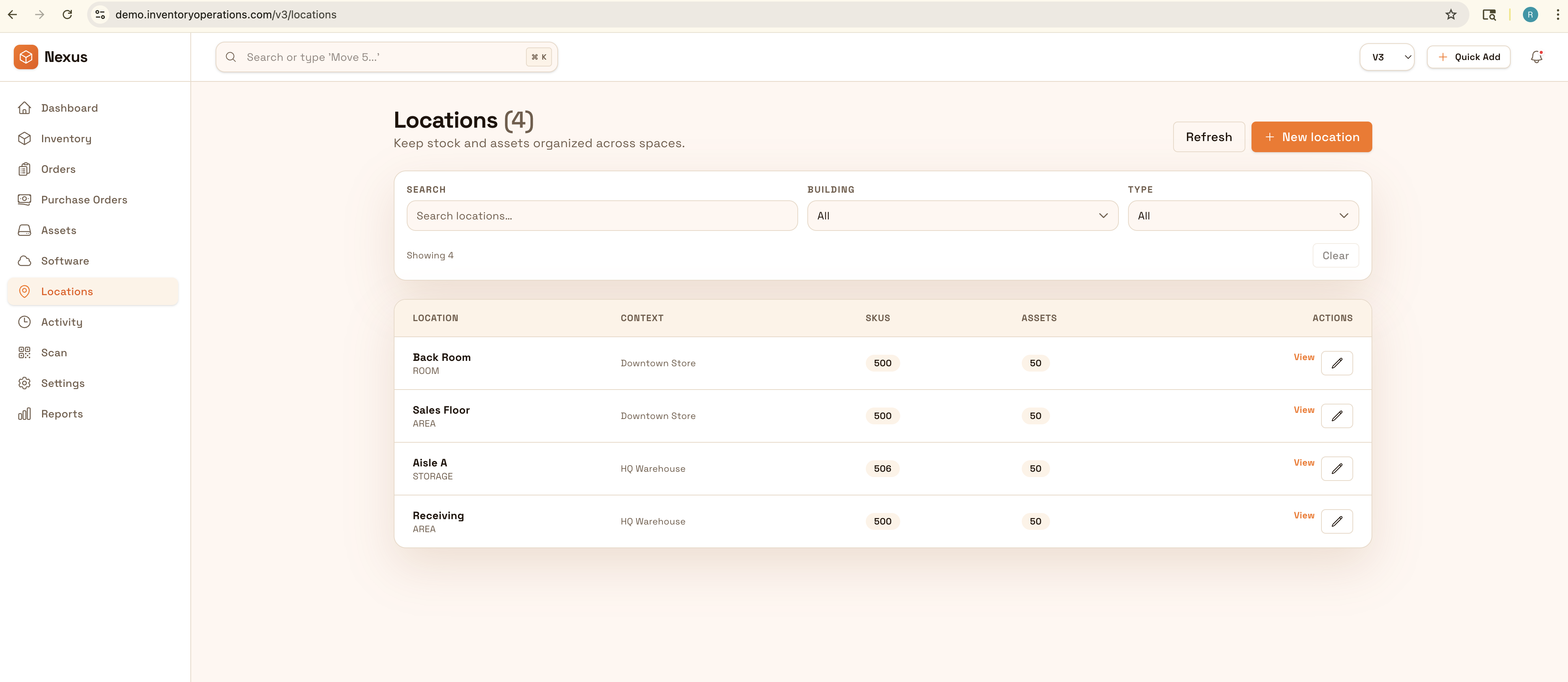

Storage, staging, and line-side locations need a trail. Record transfers so each handoff is accountable.

When adjustments lack context, investigations drag on. Use consistent reason codes and approvals to speed review.

IO standardizes tracking, controls, and evidence—so teams can operate confidently across sites and stakeholders.

• Parts, WIP, and finished goods by stage and location • Transfers between warehouses, staging, and line-side • Counts and reconciliation outcomes • Adjustments with reasons and approvals • Exportable reporting for planning and reviews

Define storage, staging, and line-side locations so transfers are traceable.

Record receiving and movement between stages to keep counts aligned.

Cycle count high-velocity areas to prevent drift and reduce surprises.

Document variance and export trends to tighten process over time.

Tell us your compliance and operational requirements. We’ll recommend the right rollout.

Use approvals for sensitive adjustments and preserve movement history so audits and investigations have defensible evidence.

The biggest wins are usually accuracy, speed, and defensible accountability.

Yes—model stages and locations so movement is traceable end-to-end.

Yes—better visibility and cycle counts surface shortages earlier.

Yes—reason codes and movement history shorten investigations.

Yes—exports support planning, purchasing, and operational reviews.

Start with receiving + key storage/staging areas, then add cycle counts.